What are HempkinZ?

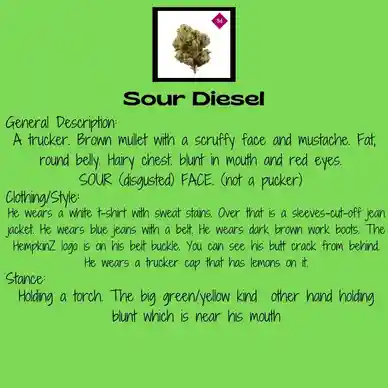

- HempkinZ are unique Canna-People; released in Annual collections of Eight (8). Each represents a favorite weed strain.

- HempkinZ Canna-People come as 3D Resin Printed - Hand Painted Statues and 2D NFT Art.

- HempkinZ TableLighters are Hand Painted, Unique and come with 2 Refillable Lighters; at an affordable price.

HempkinZ Original Designs

8 Reasons a Non-Smoker Should Own a Lighter...

- 1. Lighting Candles or Incense

- 2. Lighting the Grill

- 3. Lighting a Lantern

- 4. Starting a Campfire

- 5. Starting a Fire in the Fireplace

- 6. Lighting a Pilot Light on a Gas Oven

- 7. Lighting Stovetop Burners on a Gas Stove

- 8. Lighting Fireworks

HempkinZ Canna-People

HempkinZ has researched the most popular Cannabis strains, giving each a personality, history and back story; resulting in ‘People’ versions of each strain. Canna-People are offered in annual collections of 8.

HempkinZ Canna-People are made of hand painted, resin and stand 7” – 9” tall and 6” wide at the widest point. The Characters present on a uniform base that is 1” tall and 6” in diameter. Character names can be found on the front of its’ base, while the full color HempkinZ logo is on the back. Canna People Names are color coded to represent if the strain genetic is a Hybrid, Indica or Sativa.

HempkinZ Table Lighter Ashtray

Why Table Lighters? Why not?! At the start of the 20thCentury, Table Lighters were beginning to gain their initial popularity. During the 30s – 60s, Table Lighters were so widely used, that they became as commonplace as the cast iron skillet and a highball in the afternoon.

Fast forward to today, smaller gatherings in people’s homes have become more commonplace. Smoking is more acceptable in all forms and how many times have you heard, ‘has anyone seen my lighter?’ or ‘have you got a light?’

The time is right and the market is ready to bring back this classic at a reasonable price point.

How It's Made

The Idea in Words

It all starts with an idea. Our ideas come from many hours researching and analyzing cannabis strains. Our Cann-People personalities are created in part, from what consumers think.

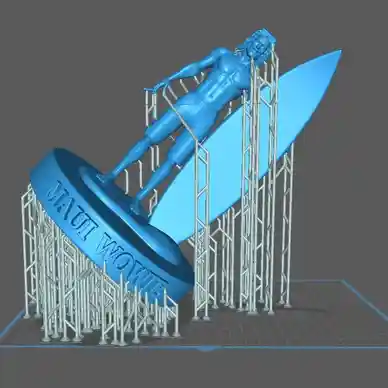

'Blending' / 'Creating'

Converting an idea into an online 3D object is not an easy nor quick task. Many hours and days are spent blending, building and revising until the perfect file is ready for prototyping.

Slicing for Printing

The slicer program takes the 3D file and ‘slices’ it into many uniform layers, as small as .02 – .05mm. The printer ‘cures’ or ‘builds’ our object one slice at a time, until it is built in one piece.

3D Resin Print Process

Our machines use an SLA / MSLA printing process which beams ultraviolet (UV) light into a tank of liquid, resin, triggering a reaction that solidifies the resin into an object.

After the Print Finishes

Once a Resin Print is completed, we use a series of steps and solvents to properly clean away any excess resin. A final curing process with more UV Light is needed before sanding and painting.

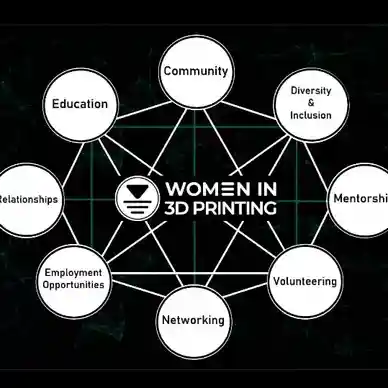

3D Printing IS Our Future

The current and ongoing advances in this technology is mind blowing. We learn by staying connected with the 3D Printing Community and Professional Organizations.